What Is Warehouse Management? A Complete Guide to Warehouse Management Systems (WMS)

Warehouse Management

Warehouse management is the backbone of efficient supply chain operations. In today's fast-paced commerce environment, having an effective warehouse management system (WMS) can make or break a business. But what is warehouse management, and how does it differ from warehouse and inventory management? This comprehensive guide answers these questions, explains the WMS complete form, and provides actionable insights on optimizing your warehouse.

What Is a Warehouse?

A warehouse is more than just a storage facility, it's the central hub of inventory management, crucial for keeping products secure, organized, and ready for shipment. When asking, "what is warehouse?", think of it as a dynamic environment where inventory flows, products are tracked, and orders are precisely fulfilled. Whether it's a small business with a single location or a multinational corporation with warehouses around the globe, understanding what a warehouse is and how it functions is key to efficient operations.

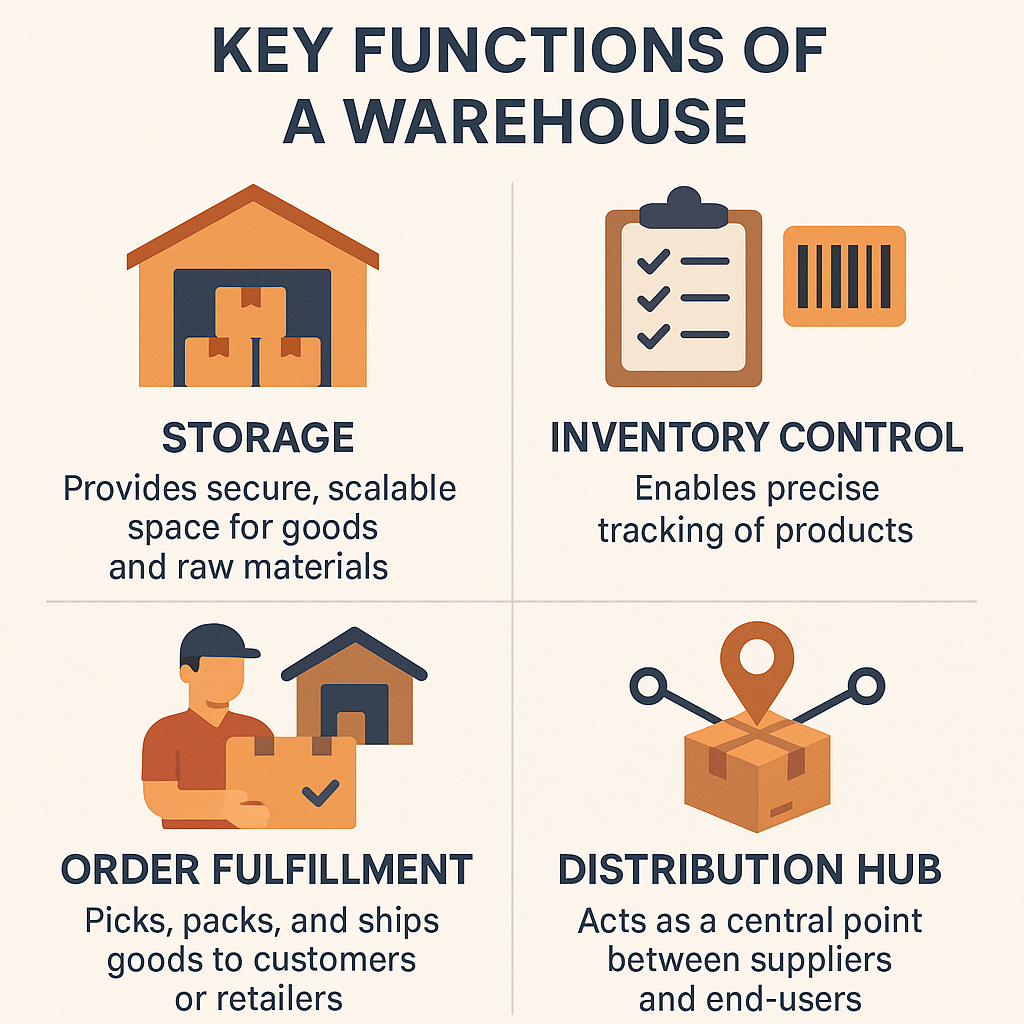

Key Functions of a Warehouse

- Storage: Provides secure, scalable space for goods and raw materials.

- Inventory Control: Enables precise tracking of products.

- Order Fulfilment: Picks, packs, and ships goods to customers or retailers.

- Distribution Hub: Acts as a central point between suppliers and end-users.

What Is Warehouse Management?

Warehouse management is the strategic process of controlling all aspects of a warehouse to ensure fast, accurate, and cost-effective shipments. But what is warehouse management in practical terms? The collective policies, processes, and technologies keep warehouses organized and inventory controlled.

Core Elements of Warehouse Management

- Inventory Tracking: Maintaining an accurate record of inventory levels.

- Receiving and Putaway: Efficient procedures for handling incoming goods.

- Picking and Packing: Optimizing how items are collected and packed for orders.

- Shipping and Delivery: Ensuring orders reach their destinations quickly and safely.

- Returns Processing: Managing the return flow efficiently.

WMS Full Form: What Is a Warehouse Management System?

WMS stands for Warehouse Management System. But what is a warehouse management system, and how does it impact warehouse and inventory management? A warehouse management system is specialized software that streamlines the movement and storage of inventory in a warehouse. When people ask about the WMS complete form, they often want to know how this technology supports effective warehouse management.

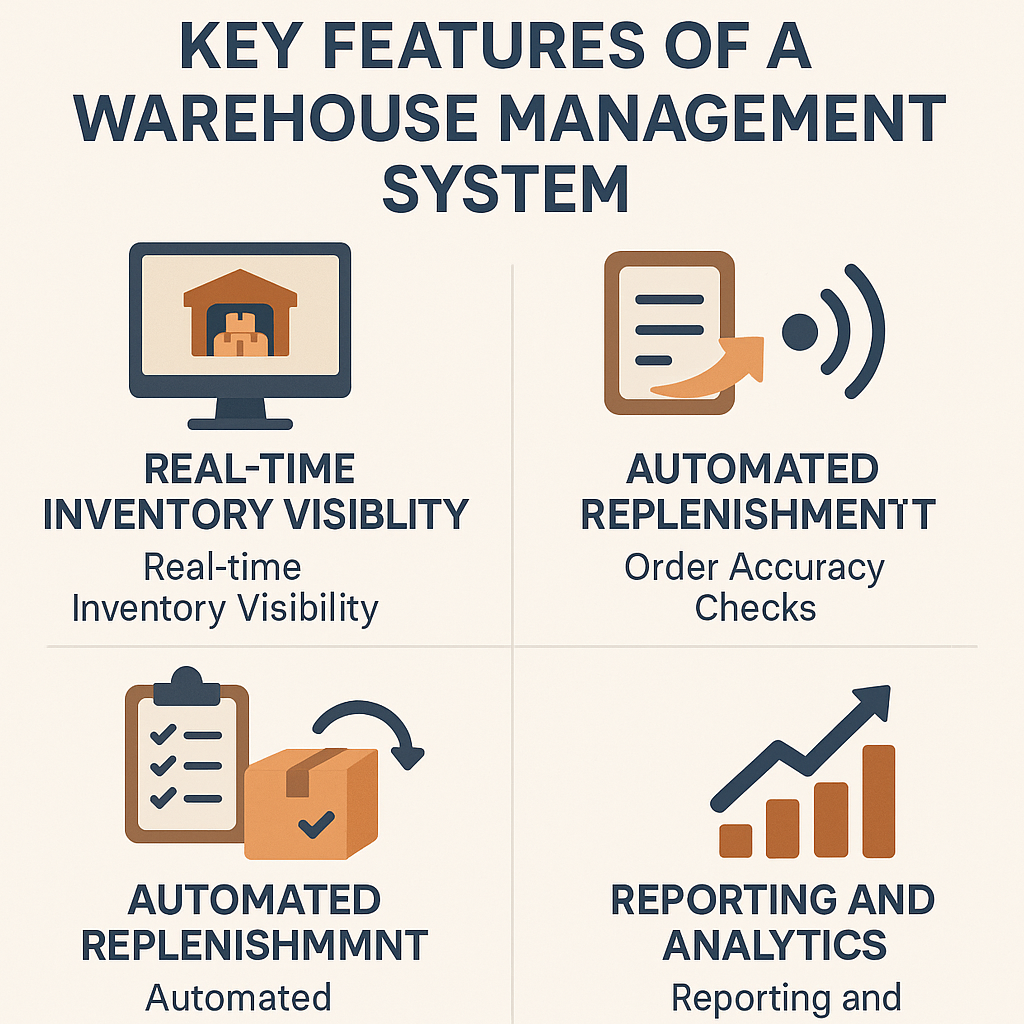

Key Features of a Warehouse Management System

- Real-time Inventory Visibility: Tracks products as they move through the warehouse.

- Barcode and RFID Integration: Speeds up both incoming and outgoing processes.

- Automated Replenishment: Ensures stock levels are maintained automatically.

- Order Accuracy Checks: Reduces human error with automated checks.

- Reporting and Analytics: Provides managers with actionable insights.

The Importance of Warehouse and Inventory Management

Warehouse and inventory management go hand in hand. While warehouse management focuses on how items move and where they are stored, inventory management ensures you always have the right products in the right quantities at the right time.

Also Read: Objectives of Inventory Management

Benefits of Effective Warehouse Management

- Reduced Errors: Fewer picking and shipping mistakes.

- Higher Efficiency: Faster turnaround on orders.

- Lower Costs: Minimises excess inventory and storage fees.

- Improved Customer Satisfaction: Orders are accurate and on time.

Warehouse and inventory management also reduce waste and free up working capital, making the supply chain more robust overall.

How Does a Warehouse Management System Work?

A warehouse management system (WMS) automates and optimizes the entire lifecycle of warehouse operations. The WMS tracks, manages, and reports every activity from when products arrive at the warehouse until they leave for customers.

Step-by-Step Warehouse and Inventory Management with WMS

- Receiving: WMS records every incoming item, assigns it a location, and updates inventory counts.

- Putaway: Guides staff on where to store the items for maximum efficiency.

- Inventory Tracking: Offers real-time views of stock levels and locations.

- Order Picking: Suggests optimized routes and batch orders for faster picking.

- Packing and Shipping: Ensures orders are packed accurately and labelled for the correct destination.

- Returns Handling: Streamlines returns into the system for resale or disposal.

By applying these steps, warehouse management becomes a question of integration, melding people, processes, and technology into a cohesive whole.

Key Challenges in Warehouse Management

Understanding what warehouse management is also means facing the realities of operational challenges:

- Inventory Inaccuracies: Manual errors and system mismatches.

- Space Utilization: Balancing storage density with accessibility.

- Labour Costs: Managing workforce efficiently.

- Scalability: Adapting to business growth or seasonal spikes.

- Data Silos: Lack of integration with other business systems.

A well-implemented warehouse management system can help mitigate most of these issues, bridging gaps between warehouse and inventory management and the broader supply chain.

Read: Differences Between Logistics and Supply Chain Management

Choosing the Right Warehouse Management System

Selecting the right WMS can transform your warehouse management. Here are important considerations:

- Ease of Use: User-friendly interfaces reduce training time.

- Integration: Seamless connection with ERPs, e-commerce platforms, and shipping carriers.

- Scalability: Grows alongside your business demands.

- Customization: Adapts to specific workflow needs.

- Support and Upgrades: Regular updates and responsive support services.

Ask suppliers for demonstrations and evaluate how each warehouse management system supports warehouse and inventory management.

Future Trends in Warehouse Management

The future of warehouse management is driven by technology and innovation. Trends impacting the space include:

- Automation & Robotics: Robots handle picking, packing, and restocking shelves.

- AI and Machine Learning: Predicts demand, streamlines workflows, and prevents stockouts.

- IoT Devices: Sensors track temperature, humidity, and location in real time.

- Cloud-based WMS: Offers scalability and remote access for multi-site operations.

Warehouse management and WMS complete form are becoming synonymous with flexibility, intelligence, and automation.

Best Practices for Warehouse and Inventory Management

- Regular Audits: Compare system data with physical inventory to spot discrepancies.

- Continuous Training: Keep staff updated on warehouse management system features.

- Slotting Optimisation: Store high-velocity items near shipping areas to speed up fulfilment.

- Leverage Data: Use analytics for forecasting and inventory planning.

- Safety First: Implement safety protocols to protect products and workers.

When asking "what is warehouse management," these best practices ensure the answer is ongoing improvement and excellence.

With the ILS Portal, you can easily set up and manage your shipping warehouse address. This feature allows you to define the exact location(s) from where your orders will be dispatched, ensuring accurate logistics and timely deliveries. Whether you operate from a single warehouse or multiple fulfillment centers, the ILS Portal streamlines the process for efficient shipping.

Conclusion

Warehouse management goes far beyond storing products; it powers the supply chain, supports fast and accurate deliveries, and underpins customer trust. Knowing what a warehouse is, understanding the WMS complete form, and recognizing the deep connection between warehouse and inventory management all contribute to a thriving, future-ready business.

Whether you're new to the field or looking to upgrade your warehouse management system, remember, success starts with informed choices and continuous optimization. Warehouse management isn't just about the present, it's about building a resilient, competitive edge for the future.

Frequently Asked Questions

What is meant by warehouse management?

Warehouse management is the process of efficiently overseeing all warehouse operations, from receiving and storing goods to picking, packing, and shipping orders. It involves managing inventory levels, optimizing warehouse layout, coordinating logistics, and streamlining workflows to ensure accuracy, speed, and cost-effectiveness throughout the supply chain.

What is SAP in a warehouse?

SAP in warehouse management refers to SAP Warehouse Management (SAP WM), a module in SAP ERP that helps automate and optimize warehouse operations. It supports inventory control, goods movement, bin management, and real-time tracking of materials.

What are the 5 essential warehouse management processes?

The five key processes in warehouse management are: Receiving goods, Putaway (storing items in designated locations), Picking (selecting items for orders), Packing, and Shipping.

How do you manage a warehouse?

Warehouse management involves using systems like a Warehouse Management System (WMS) to monitor inventory levels, track goods, manage staff activities, automate processes, and analyze performance for better efficiency and accuracy.

What is a Warehouse Management System (WMS)?

A WMS is software that helps streamline daily warehouse operations, such as inventory tracking, order management, replenishment, and reporting, ensuring real-time visibility and control over goods and logistics.

Why is warehouse management important for eCommerce businesses?

Effective warehouse management ensures fast order processing, reduced errors, accurate inventory tracking, and on-time delivery, all of which enhance customer satisfaction and improve profitability in eCommerce.

What is the difference between warehouse management and inventory management?

Warehouse management focuses on the physical storage, movement, and organization of goods within the warehouse. Inventory management, on the other hand, deals with tracking stock levels, forecasting demand, and maintaining optimal inventory quantities.